bespoke geometry

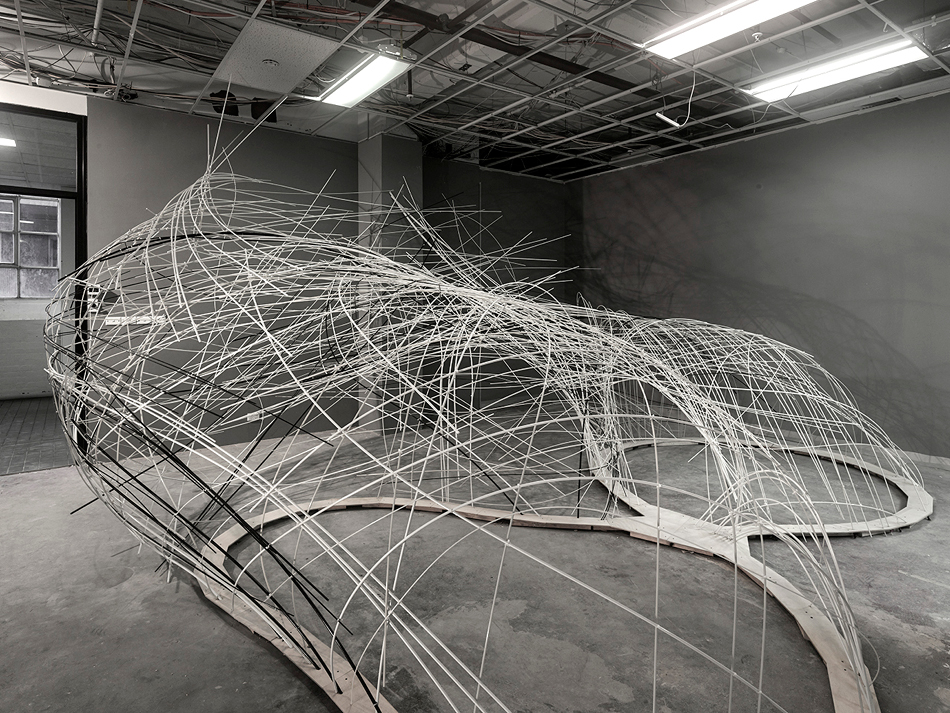

The Social Weavers

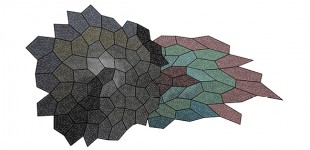

The Social Weavers is a bending active, non-standard grid shell structure made from fibre composite rods of variable diameter and stiffness. The installation develops aggregate self-forming processes that intersect with the behavioural activation and distribution of fibre-composites under design direction for the production of a novel architecture. The Social Weavers installation is conceptualised as a nest. It is comprised of multiple, actively-bent splines that are articulated through a network of collected, interwoven elements, whose local behaviours aggregate into a globally non-linear structural assembly. The central component of the design model for the Social Weavers is the custom-written, verlet-integrated particle simulation library that is set up specifically to allow for collections of particles to be organized through unfixed and transitional topologies. It allows for the incremental addition of new elements over time, and for existing elements to continuously undergo reassessment of the force relationships in which they participate.

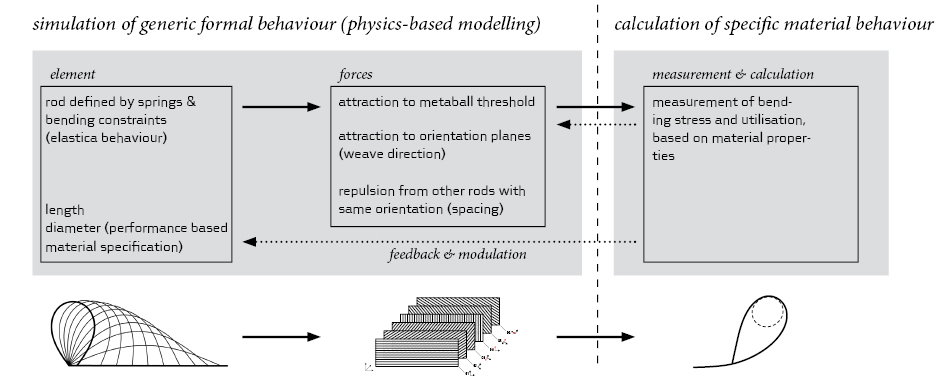

Model process diagram

Operation of the design model for the Social Weavers consists of establishing the parameters of the scalar field that will be used to shape the morphology of the assembly, determining a set of different weave orientations for arraying the actively bent splines in space, and finally, during the execution of the simulation, incrementally releasing splines elements into the design space and allowing for them to self-organize within the designer-set parameters. At any time during this modelling phase, the designer is capable of making adjustments to any of these forces, effectively reorienting elements or adjusting the underlying scalar field that drives the general organisation of individual elements.

For the simulation of the individual elements, forces that have been demonstrated to effectively describe the elastica-driven behaviour of elements operating in active bending are deployed. Each spline is subdivided into an appropriately-dimensioned subset of particles for defining both the springs which use Hooke’s law for resolving elasticity in the long axis and the vector-normal method for resolving the forces applied for the description of elastic bending behaviours. The vector-normal method is developed by Daniel Piker and Moritz Fleishmann as a simplified derivation of a more complex method developed by Barnes, Williams and Adriaenssens.

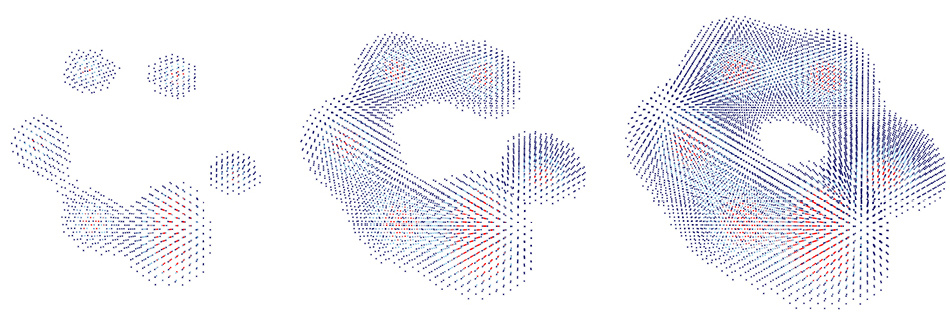

Forces developed for generative design simulation

In addition to these “natural” forces which effectively describe environmental and material behaviours in the design model, the Social Weavers also relies on a series of “artificial” forces that empower the designer to more directly assert agency in a design process that relies on unfixed topologies that undergo continuous transformation during simulation. These forces create influence on the organisation of the splines in multiple capacities: 1. for movement along the gradient of a scalar field, 2. according to a series of planar orientations, and 3. as instruments for creating separation between splines that share these orientations.

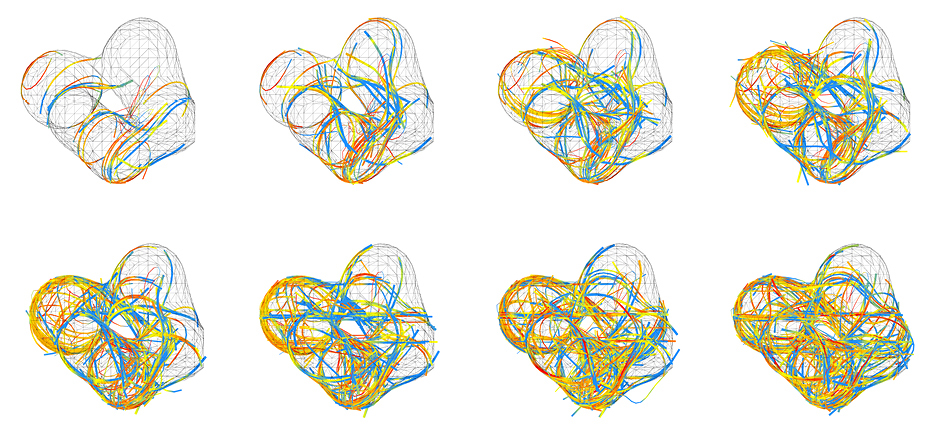

Scalar field as target geometry

Operation of the design model for the Social Weavers consists of establishing the parameters of the scalar field that will be used to shape the morphology of the assembly, determining a set of different weave orientations for arraying the actively bent splines in space, and finally, during the execution of the simulation, incrementally releasing splines elements into the design space and allowing for them to self-organize within the designer-set parameters. At any time during this modelling phase, the designer is capable of making adjustments to any of these forces, effectively reorienting elements or adjusting the underlying scalar field that drives the general organisation of individual elements.

Unlike many nests which are designed for smaller units of birds, the geometric variation of the Social Weavers is an expression of the multiple distinct spatial conditions required of the complex social organisations emblematic of the nests of the birds after which the installation takes its name. For the design model, this diagram for growth is interpreted by considering morphogenesis as a response to a scalar field condition. In order to achieve local differentiation, this field is defined using a metaball falloff function with multiple centroids, and any number of points and associated radii, together with a threshold value, can be used as inputs for the centroids. Their number can be increased or decreased at any time during the simulation, and the threshold can also be adjusted, making significant topological change possible.

Incremental layering of active-bent members

The scalar field force applied for the Social Weavers contrasts with forces in many simulation engines that rely on target geometries for either pulling or repelling particles. In these latter instances, forces typically rely on closest point calculations to determine the vector of influence on a given particle, movement that is purely normal to the target geometry. For the scalar field sample gradient force, however, each particle continuously samples itself within the field being evaluated. Each particle then senses the space around itself and determines the vector that indicates the optimal direction for movement towards the designer-defined ideal field threshold. With metaball fields, this then does not necessarily result in movement toward the normal of the surface condition, but can in fact reflect movement along the isosurface interior, or between apparent ideals. The process of sampling this field for each particle rather than pulling them to a design mesh – fixed or unfixed – then allows for the actively-bent splines to engage in a more nuanced force-based relationship with the design environment as they reflect a direct dialogue between design and material agencies.

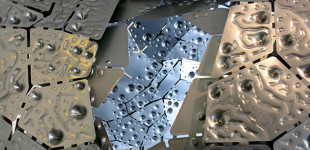

Member material specification

Finally, the simulation is coupled with a dynamic system for material specification. The relaxation of the elements is affected by multiple forces as described above, which require the element to be either straighter or more curved. Each element begins with a 10mm diameter specification, which changes as the element encounters differing conditions. Change in diameter is driven by utilisation, as a function of bending stress, which is calculated each iteration. If an element is utilised by greater than seventy per cent, meaning that it needs to negotiate higher curvature, it reduces its diameter by one step. If an element is utilised by less than thirty per cent, meaning that it is straighter, that element increases its diameter by one step. The diameter steps are 2, 4, 6.25, 8 and 10mm.

The design possibilities of this new approach were investigated and tested in a 5-day experimental design & build workshop held in Melbourne and led by Paul Nicholas from CITA and Tim Schork from the University of Monash. The workshop aimed to introduce students to the ways by which new digital-material practices allow digital design data and behavioural simulation into the process of materialisation, through the design of pre-calibrated, bending active composite material assemblages.