bespoke geometry

Il Trittico

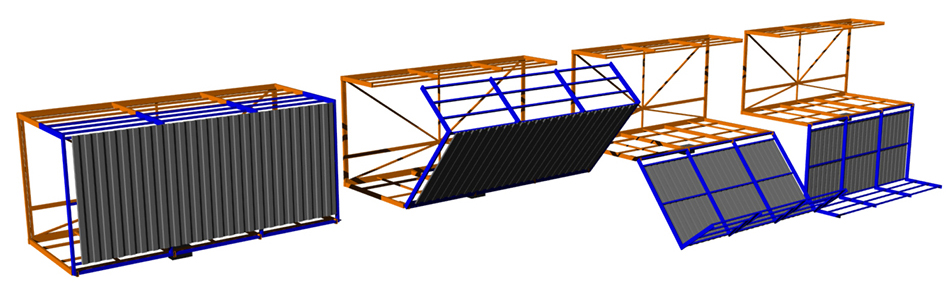

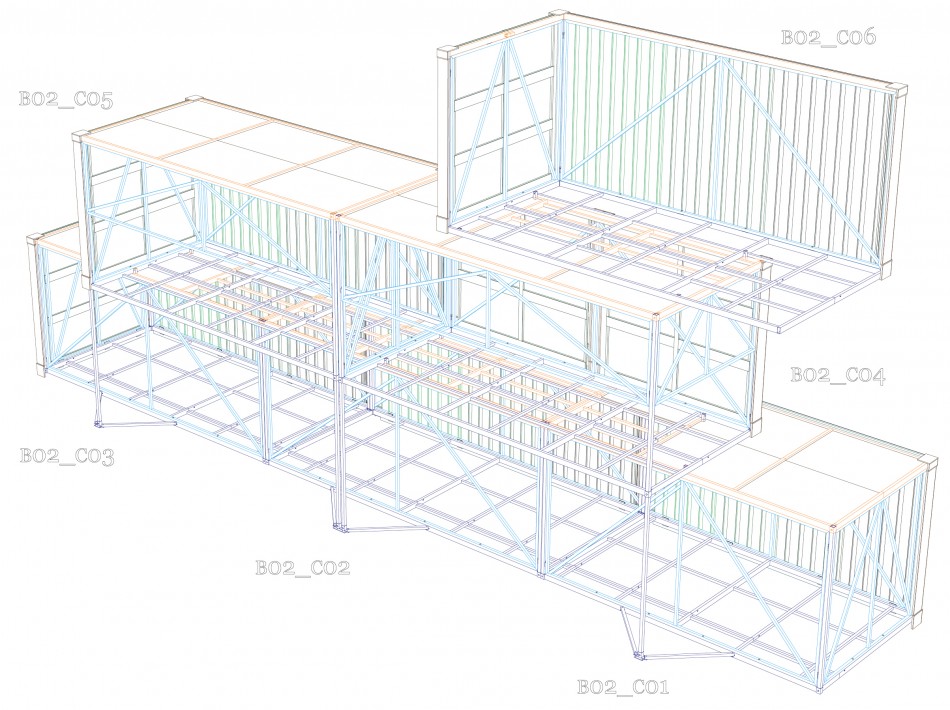

The set for the Royal Danish Opera’s production of Puccini’s Il Trittico is comprised of a collection of shipping containers which change their configuration both within and between each of the three distinct stories that constitute the whole of the show. This project entailed working with the drawing studio and construction team at the Theater’s Scenic Workshops, developing both the detailing and specification/representation for the assembly system of the primary set pieces. The outwardly identical appearances of the containers belies the varied performance requirements of the individual containers. Some have the containers are mechanized with faces that open on motorized hinges. Others fly in and out on chains, or have faces that are removeable. Although the set was fabricated in Copenhagen, this was co-produced with the Vienna Opera, and was staged in both cities.

- Shipping containers

- Dropped from ceiling

- Opened with flyaway doors

- Opened with swing mechanisms

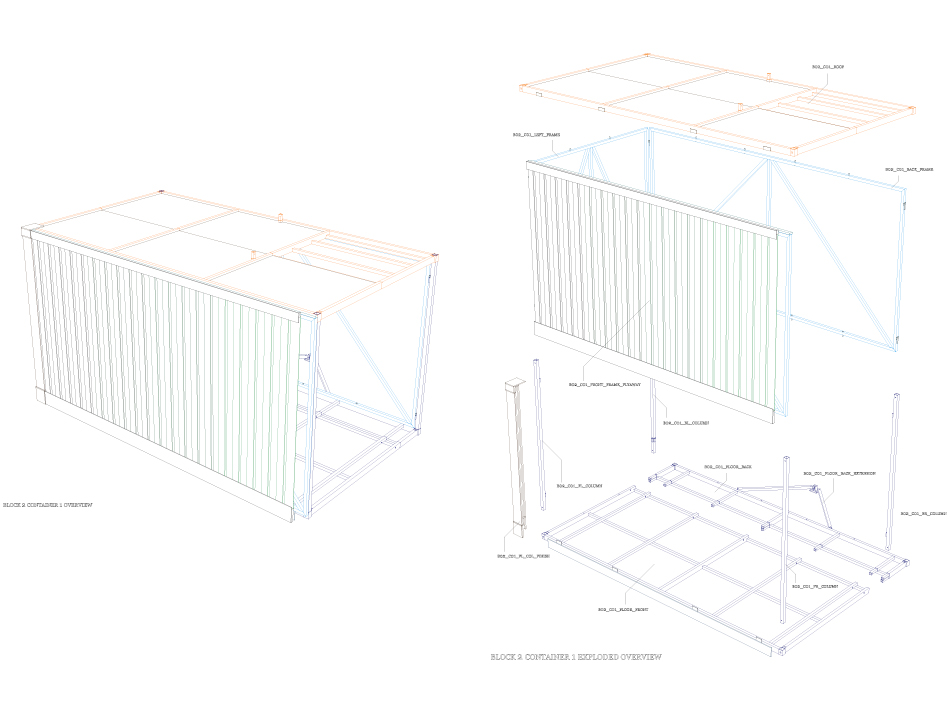

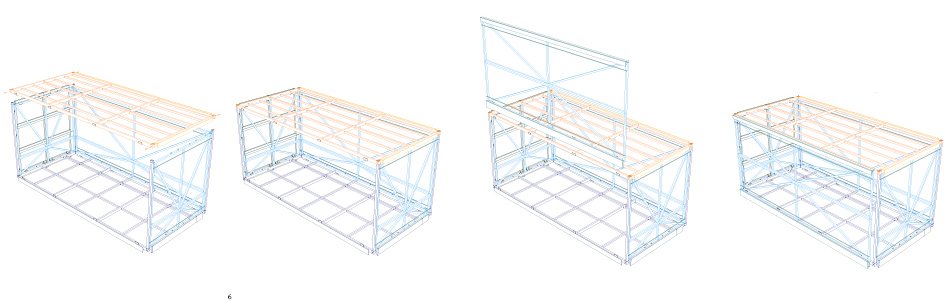

The entire set had to be easily broken down and shipped between the two cities, and there were significant time constraints for the assembly of the components upon their arrival: in Vienna, the production crew had only two days to build up the entire set from the pieces shipped from Copenhagen. This demanded a detail system that allowed for rapid installation and removal, and a mode of representation that would enable the crew to quickly understand and construct containers.

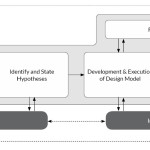

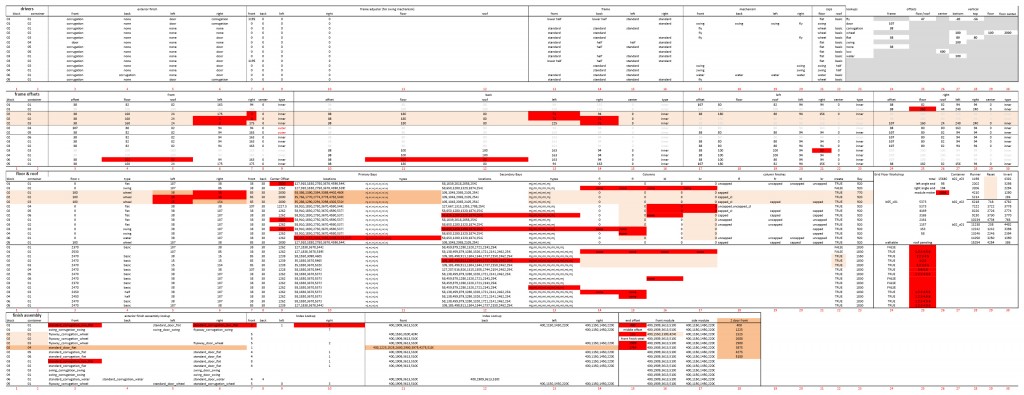

Data-driven modelling: the excel-based dashboard for the model, which specified assembly details in a fully resolved 3D model

Data-driven modelling: the excel-based dashboard for the model, which specified assembly details in a fully resolved 3D model

Overview drawings of a single container

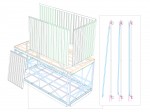

Sketch of motorized hinge steel framing

Details and fabrication

Assembly ordering